- Home Page

- Company Profile

- Our Products

- Contact Us

incremental encoder

25000 INR/Piece

Product Details:

- Frequency 100 kHz max

- Cable Length 2 meters

- Load Capacity 30N axial

- Mounting Type Flange, Clamp

- Weight 280g

- Automation Grade Automatic

- Drive Type Shaft

- Click to View more

X

incremental encoder Price And Quantity

- 10 Piece

- 25000 INR/Piece

incremental encoder Product Specifications

- Flange, Clamp

- Compact design, High resolution, Rugged construction

- 280g

- Wired

- Digital

- Optical

- 5W

- 30N axial

- 100 kHz max

- Single phase

- 2 meters

- 0 to 6000 rpm

- Embedded microcontroller

- -20C to +80C

- 5V to 30V DC

- Automatic

- Aluminum alloy, Stainless steel

- IP65

- Industrial machinery, Automation, Robotics

- Shaft

Product Description

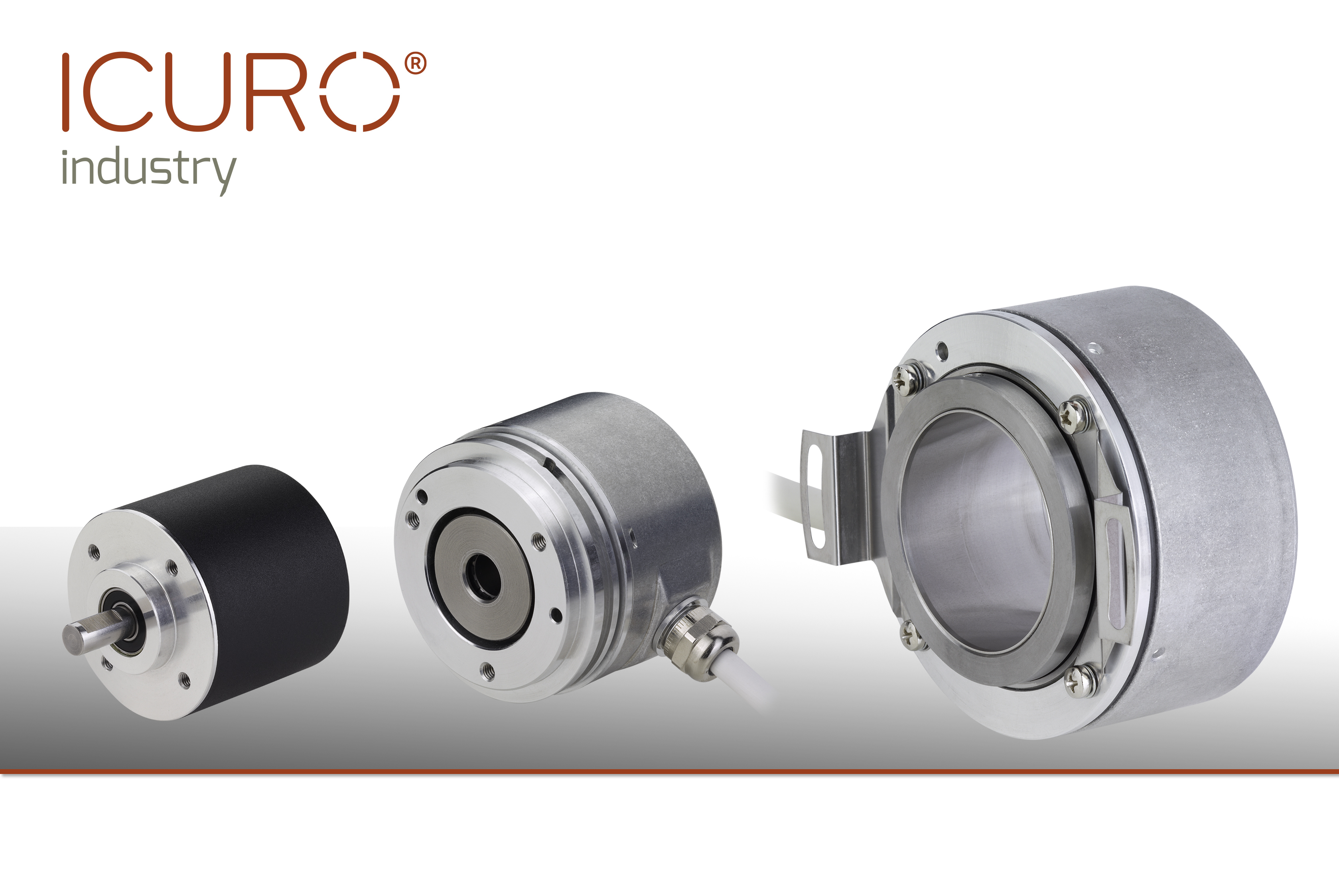

Incremental Optical Rotary Encoders- Functional Safety Rotary Encoders

- Magnetic Rotary Encoders

- Hall Effect Sensors

- Potentiometers

- Draw Wire Solutions

- Inclinometers

- Electronic Modules

- Swift Comm Wireless Encoder Interface

They are available in various types of assembly configuration:

solid shaft

blind shaft

hollow shaft

The ATEX range provides solutions for explosive environments in all of our encoder technologies (incremental, absolute, tachosencoders), with intrinsically safe and explosion proof encoders.

High-Resolution Performance

Featuring 1024 pulses per revolution, our incremental encoder ensures precise detection of angular position and speed. This high resolution is essential for applications demanding accurate real-time feedback, particularly in complex automation systems and robotics.

Durable and Reliable Construction

The IP65-rated housing, built from aluminum alloy and stainless steel, offers exceptional resistance to dust, water, vibration, and shock. Designed for tough industrial environments, the encoder provides consistent operation even under harsh working conditions.

Flexible Output and Signal Compatibility

This encoder supports both push-pull and open-collector output types and is fully compatible with TTL/HTL signal levels. The three-channel output allows seamless integration into various digital control systems, maximizing operational flexibility.

FAQ's of incremental encoder:

Q: How does the incremental encoder provide precise speed and position feedback?

A: The encoder utilizes optical sensing with an infrared LED and delivers 1024 pulses per revolution through A, B, and Z channels. This configuration allows accurate digital readout of rotational speed and position for industrial controls and automation.Q: What are the benefits of the IP65 housing and rugged design?

A: The IP65 housing ensures protection against dust and water ingress, while sturdy aluminum alloy and stainless steel materials guard against mechanical stress, providing reliability and extended service life, especially in demanding industrial settings.Q: When should I choose TTL or HTL-compatible output signals for the encoder?

A: TTL output is suitable for applications requiring fast, low-voltage digital transmission, while HTL is ideal for high voltage and longer cable runs in noisy environments. Selection depends on your control system and signal integrity needs.Q: Where can the incremental encoder be installed, considering mounting and connectivity?

A: Thanks to flange and clamp mounting options and a 2-meter shielded PVC-insulated cable, the encoder can be easily installed on various shafts and machinery in industrial automation, robotics, and production lines.Q: What process is involved in integrating the encoder with automation systems?

A: Integration involves mechanically securing the encoder via its flange or clamp, electrically connecting its shielded cable to the digital controller, and configuring signal channels A, B, and Z for correct position and speed feedback.Q: How is the encoder protected against vibration and shock during operation?

A: Engineered with resistance to vibration (10-2000 Hz, 10g) and shock (100g, 6ms), the encoder maintains stable performance by using high-quality bearings and robust housing, ensuring accurate data transmission in dynamic environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email